As a roofing professional, you defy gravity and stroll across steeply sloped surfaces to earn a living. In your line of work, your feet are off the ground.

No one afraid of heights aims for a career as a roofer. But even if you get a certain thrill each time you’re up there with a bird’s-eye view, you understand there are dangers to treading on a rooftop.

It takes more than guts to work as a roofer, though. It takes crucial roofing safety precautions to make it home at the end of the day.

Roofers place third in the top 10 most dangerous jobs in the world. According to the Bureau of Labor Statistics, roofers have one of the highest rates of injuries and illnesses of all occupations.

In both the United States and Canada, roofing work is consistently cited as one of the most dangerous jobs nationally. They also have one of the highest rates of workplace fatalities.

In this article, we’ll review what makes your job so perilous. And we’ll explore precautions you should take to protect yourself from serious injuries and even death.

RELATED ARTICLE: How to Find, Train, and Retain a Quality Roofing Crew

Overview of Roofing Safety

While the view from the top might be exhilarating, the roofing profession is riddled with risks that demand a constant focus on safety. Here are some concerns:

Falls: Falls are the leading cause of serious injuries and fatalities in the roofing industry. You work at heights. Roofs often have uneven surfaces. Sometimes, conditions are slippery. One misstep can have devastating consequences.

Electrocution: Electrical hazards pose a significant threat for roofers. Overhead power lines and exposed wiring can be dangerous. Faulty electrical equipment is another concern. Electrical shock can be life-threatening and must be addressed immediately.

Heatstroke: Up on the roof, exposure to intense heat and direct sunlight can lead to dehydration and heat exhaustion. Heatstroke can be fatal.

Exposure to hazardous materials: Roofs can harbor hidden dangers from lead paint to asbestos. Respiratory problems and eye injuries are real concerns.

Burns: Working with hot tar and other roofing materials risks burns and danger from fume inhalation.

Musculoskeletal injuries: You spend a lot of time on your knees working on sloped rooftops. Roofers often suffer from musculoskeletal disorders (MSDs).

The bottom line is that roofing is a risky business. In the United States, it is regulated by the Occupational Safety and Health Administration (OSHA). The federal agency’s mission is to ensure safe and healthful conditions in the workplace.

Roofing safety measures are not pesky rules imposed upon your profession. Regulations are essential for preventing accidents and injuries. And there are defensive strategies you can use to minimize risks.

Understanding OSHA Standards for Roofing

OSHA is a vital government agency dedicated to protecting the health and safety of workers. It is part of the U.S. Department of Labor.

It provides training, outreach, education, and assistance. OSHA sets and enforces workplace safety standards that employers must follow by law.

For roofers, OSHA standards are critical for preventing accidents and injuries. Every employer in the roofing industry has a legal obligation to provide a safe workplace. They must train their workers and provide the necessary equipment to keep them secure on the job.

What are some essential OSHA requirements for roofing safety?

- Fall protection: Employers must provide fall protection systems. It is one of the most crucial OSHA roofing safety requirements. Are you working more than 6 feet above workers below you? You need fall protection.

- Personal protective equipment (PPE): OSHA mandates specific PPE for roofers, such as hard hats, eye and hearing protection, gloves, and non-slip footwear. PPE is critical to safeguard you against potential roofing safety hazards.

- Safe roof access: Whether you use ladders or scaffolding, roof access is how you get up to and down from a roof. OSHA’s guidelines are essential for a safe work environment. Regulations include proper training, regular inspections, and compliance.

- Hazard training: OSHA requires proper training to work with hazardous chemicals. You must qualify to handle any dangerous materials you may encounter on the job.

Essential Roofing Safety Training

Since falls are the leading cause of roofing injuries, the primary concern of OSHA’s safety training for roofers is fall prevention.

Proper training equips you with the knowledge and skills to use fall protection systems. Systems can include guardrails, safety nets, or personal fall arrest systems (PFAS) such as harnesses and lanyards.

Although most deaths are due to falls, electrocution and burns from tar are also hazards of the industry. Hot roofs during the summer cause heat-related illnesses.

Essential training includes how to handle emergencies and provide first aid. The correct way to operate and maintain roofing equipment is emphasized.

Here are some key safety measures:

Personal Fall Arrest System

A PFAS is designed to catch and suspend you if you fall from a height. It is a full-body harness or vest. A lifeline or lanyard device connects the harness to an anchor point. The anchor is a secure structural element like a roof beam, strong enough to hold weight and withstand the fall.

Equipment Handling and Maintenance

Nail guns. Saws. Ladders. Roofers work with dangerous equipment and tools.

You must understand the function of each tool and how to use it. Proper maintenance also keeps tools and equipment functioning well, decreasing the risk of injury.

Emergency Response and First Aid

Roofing requires a lot of heavy lifting. You should learn the correct posture to reduce muscle strain and injury.

It’s also important to have basic first aid skills like CPR and wound care. You should understand emergency response procedures for fires, falls, and chemical spills.

OSHA-compliant training is not only crucial for roofers—it’s a matter of life and death. It is vital to continue to learn and follow safety rules. Speak up when you see any unsafe practices on the job site.

RELATED ARTICLE: How You Can Keep Your Salespeople Safe…and Off Your Insurance

Case Studies/Examples of Safety in Action

It’s usually roofing accidents and deaths that make the news and get written into OSHA reports. However, roofing companies also report encouraging news about how using roofing safety measures has saved lives.

For example:

Peak of Perfection Roof Cleaning

In a roofing forum, Kevin Enderle, owner of Peak of Perfection Roof Cleaning, tells how roofing safety measures saved his employee’s life:

“I watched as he stepped onto the roof, and his feet immediately went out from under him… he went tumbling down the roof on his butt, completely unable to stop and gaining speed… until his safety harness and lanyard brought him up short of the edge… exactly as designed. The anchor, installed not 15 minutes before, did its job.

“It was a very long way down. Had he not been wearing a safety harness and I hadn’t insisted on installing safety anchors, I would have been at the hospital right now, very likely devastated.

“My guys grumble about having to put the anchors in. They grumble about wearing the harness. They are young and feel indestructible. Gravity knows otherwise. I can absolutely 100% GUARANTEE I will never hear another complaint about anchors and harnesses from him again.”

Even with all the regulations and monitoring that OSHA provides, some bad players still think they can cut corners. They put profit over the safety of their roofers. Fortunately, they do get caught, and it’s often financially devastating.

For instance:

Adrian Construction Group

Adrian Construction Group in New Jersey was fined over $1 million when a recent OSHA investigation identified six willful safety violations. Lack of fall protection, hard hats, and eye protection, as well as unsafe scaffolds, put them in the news.

And it wasn’t the first time. Adrian Construction Group has been inspected five times since 2016. Each time, violations were found. The company is now in OSHA’s Severe Violator Enforcement Program.

“Adrian Construction, under the ownership of Adrian Perea, continues to show a blatant disregard for the safety of their employees,” said Doug Parker, OSHA Assistant Secretary of Labor. “Placing them on the list of severe violators will intensify our scrutiny of their operations.”

Technological Advancements in Roofing Safety

Drones for roof inspections. Virtual reality (VR) training. Smart gear. These and other advances in technology have improved workplace safety. They also make it easier for businesses to stay safety-compliant.

Employers can use on-site cameras to monitor their employees. With a quick online search, roofers can see if their company is following workplace safety regulations.

VR can safely reenact dangerous situations without fear of employees becoming injured. Employees can use VR to train to improve their reaction time during an emergency.

Advanced PPE is also evolving rapidly. Smart helmets can be equipped with high-definition cameras and smartphones. Sensors, internet connectivity, and voice command are available features, as well as GPS, fall detection, and even a panic button.

Tech has made roofing startups more competitive and productive.

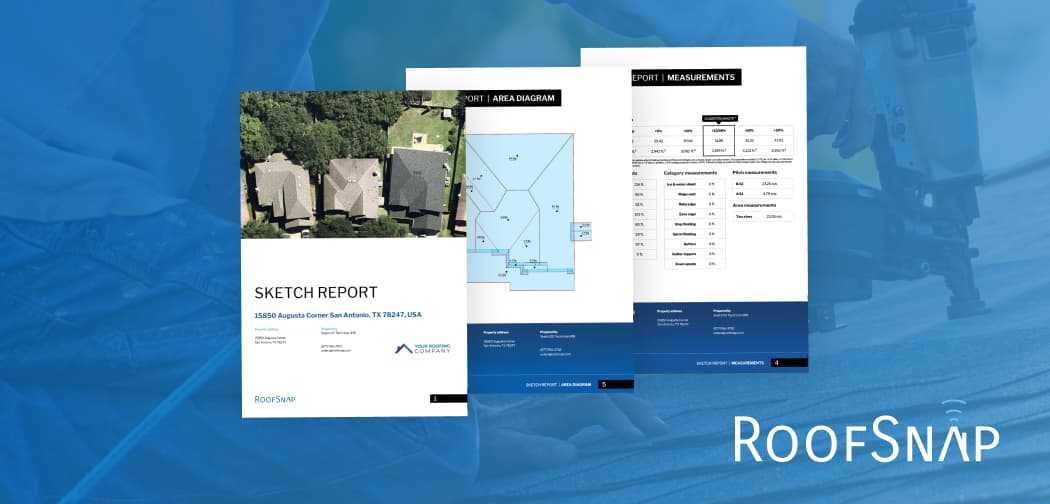

Imaging technology has revolutionized site inspections and eliminated the need for manual labor. Roofers can use cloud-based roofing software to create remote measurements and estimates.

Roofing software lets you streamline your measurement and estimation process.

Although your team will always need to climb onto the roof for replacements or repairs, leveraging software like RoofSnap—founded by a former roofer—can significantly reduce their on-site time.

With digital roofing tools, they can efficiently measure roof dimensions and even utilize direct ordering features for precise measurements. And all without ever needing to climb up in person.

These tools also streamline the process of generating estimates and quotes. They allow roofers to produce accurate figures quickly and effortlessly. Increased accuracy and time-savings lead to more sales and, of course, more revenue while decreasing the risk of injury.

If remote measurement tools interest you, you might want to see what they’re all about before committing. RoofSnap will give you a seven-day trial and your first measurement order for free when you start their service today.

RELATED ARTICLE: Roofing Apps for Contractors in The Residential and Commercial Roofing Industry

How You Can Start Implementing Roofing Safety Standards and Training Right Now

Even small, low-cost actions can improve safety on the job. Here are some tips for roofing safety you can use right away:

Use Free Online Resources.

The internet is your best resource for staying current on safety regulations and precautions. Many agencies and safety organizations offer free online resources on roofing safety. Even YouTube is a good resource for free roofing safety videos.

Inspect the Job Site.

Have a competent team member conduct frequent and regular job site inspections to identify and correct hazards.

Check Ladders.

Make sure ladders are extended at least 3 feet above the upper landing surface for stability. Be sure employees do not carry loads while using ladders.

Hydrate.

You know that cool water bottle you’ve been lusting after? Go ahead and buy it. Adequate hydration keeps you thinking straight and helps prevent heatstroke—both important factors to staying safe on a roof.

RELATED ARTICLE: Severe Weather Roofing: Best Practices for Roofing Companies